Part Sticking Issue and Ways to Address the Problem

One of the toughest aspects of 3D printing is to get your prints to stick to the build surface or bed platform. The following are the top five reasons you're having trouble and how to correct each issue:

1) Unlevel bed/printing surface -- The number one reason why you would have trouble with your parts not sticking is a uneven build plate. This problem can also lead to part warpage and/or gaps in between layers. You can learn how to level your bed by visiting this page: bed leveling guide

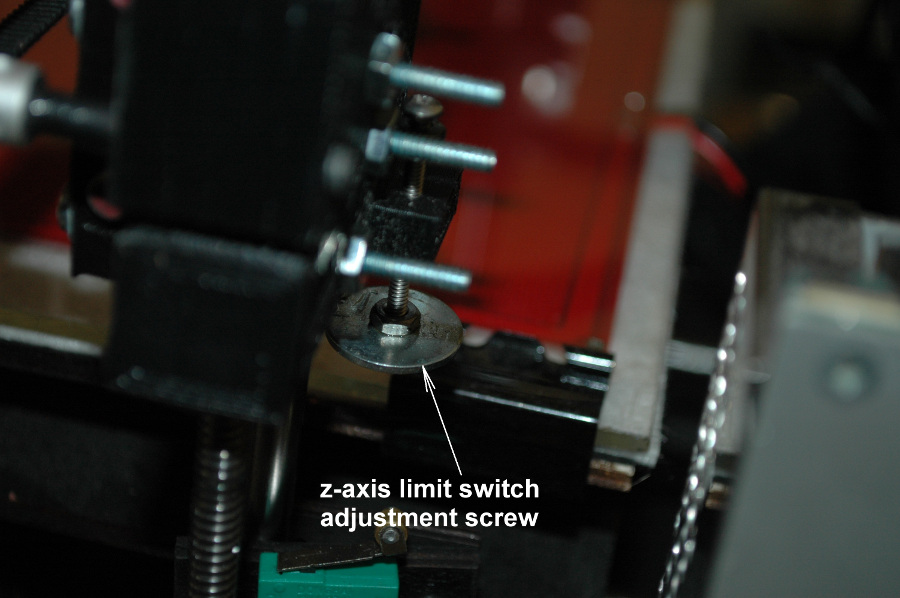

2) First layer gap -- Even if you have a completely level bed, the first layer height or gap between the nozzle and the bed is crucial to success. To check your 3D printers first layer height move the nozzle to the middle of the print bed and click the z-axis home button in pronterface. Watch the nozzle as it approaches the glass bed plate, if the nozzle strikes the glass adjust your z-axis limit switch screw down so it increases the gap. When your 3D printer is laying down the first layer it should look flat, not round and it should be pushing it on. If its just laying the plastic down adjust the z-axis limit switch screw up so it decreases the gap.

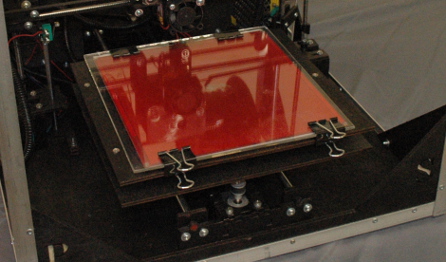

3) Bed Temperature -- If you have a heated bed, increasing the bed temperature will help get your parts to stick. A hotter bed heats the air around your part which helps prevent ABS parts from cooling and contracting and popping right off!

4) Drafty room -- You might not be able to see them, but air flow through or around your 3D printer can wreck havoc on your prints and that includes sticking issues. Tape or clip cardboard or plexiglas on the sides of your 3D printer and see if your issues get better. You'll be surprised how often this is the issue and its easy to fix.

5) Kapton tape, blue painters tape and hairspray -- When all else fails and you just can't get your prints to stick, then there are some additional surface preparations that might help. Spraying hairspray on your build glass helps with both PLA and ABS and a very easy method to try. However, not all hairsprays work the same, we've found the unscented aqua net brand to work pretty good. For ABS users, Kapton tape can help to get your parts sticking and for PLA users, the blue painters tape from the local hardware store works great. Another option for PLA users is acrylic. Place a piece of acrylic on your build glass and adjust your z-axis limit switch to accommodate the height difference, the PLA clings to acrylic and it can very difficult to get your part off!

Additional tips for parts not sticking to your bed

Always ready to try something else!