Open Source 3D Printer

-

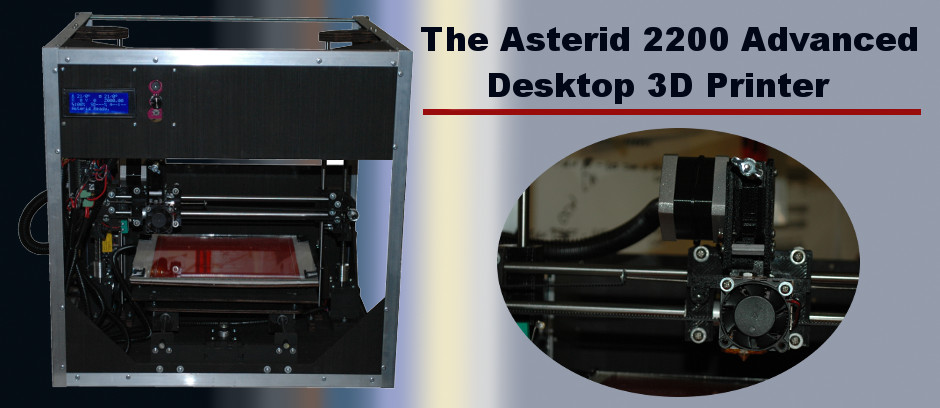

Asterid ? A Professional 3D Printer

MoreThere's a new printer in town and it will impress with the best! Our first generation desktop 3D printer is loaded with features that matter most. Dollar for dollar its the best 3D printer on the market.